Centritec Non-Contact Seals

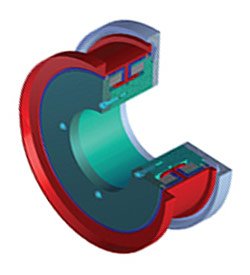

Carlyle Johnson's patented Centritec Non-Contact Seals feature a double-seal design that keeps lubricants in, and keeps contaminants out, even when idle.

Centritec seals, often referred to as centrifugal pressure seals, are a unique and cost-effective solution for sealing challenges in extreme environments, including applications such as turbines, rolling mills, railroad cars and locomotives, off-road construction vehicles and wind power generation.

Centritec Non-Contact Seals are extremely efficient components and operate with minimal parasitic drag.

In addition, the rotating chamber sealing method significantly reduces operational speed requirements, compared to typical non-contact seals, and allows the use of extremely low viscosity fluids, even as low as water.

Carlyle Johnson's experienced engineers can custom-design a Centritec non-contact seal to your exact needs, contact us for more information. Read the white paper.

Features of Centritec Non-Contact Seals

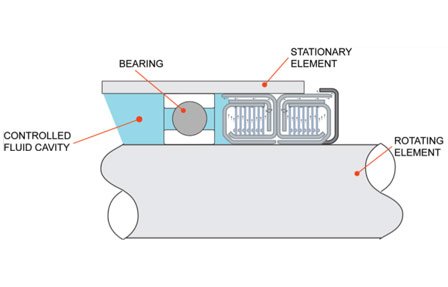

CJM's Centritec Non-Contact Seal centrifugal sealing function offers an extremely flexible solution for a variety of lubrication methods. The seal can separate (or seal) two fluid mediums from each other, such as oil and water. The unit is also capable of pumping lubrication from the seal to the bearings, while operating in oil or grease.

The Centritec centrifugal pressure seal also solves the alignment issues associated with other labyrinth seals, by actually pumping fluids to create a pressure differential between the environment and the controlled fluid cavity. This advantage is not available in either the standard contact lip type seal or the labyrinth seals, and allows for some flexibility in axial alignment.

Overview - Centritec

Non-Contact Seals

Advantages

- Less downtime

- Less maintenance

- Long lifespan

- Highly efficient

- No special tools required for installation

- Easy to install

- Can separate two fluid mediums from each other

Operation

- Lubricant contained and contaminants prevented even when idle

- Capable of continuous high-speed operation

- Seal allows for flexibility is axial alignment

- Minimal parasitic drag

- Operates in extreme temperatures

- Capable of pumping lubrication from seal to bearing when operating in oil or grease

Customization

- Custom designs available

- Alterations to standard seals available

Applications

- Turbines

- Rolling mills

- Railroad cars and locomotives

- Off-road construction vehicles

- Wind power generation