High Torque, Spring Applied Brakes (HTB)

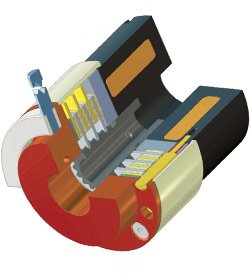

Model HTB multiple disc, spring applied brakes are designed to be a cost effective solution when especially high torque is required in an extremely small package.

The high-torque electric brake is released (disengaged) when power is applied to the brake coil. Braking torque is applied when the power to the brake coil is removed.

Common HTB spring applied brake applications include medical imaging head positioning, stopping and holding in mechanized handling equipment, servo drive brakes and emergency stopping brakes for radar, aerospace, military, construction and commercial utilities.

As with all Carlyle Johnson Machine Co products, we can custom design and manufacture high-torque, spring applied brakes to meet your exact needs.

Features of HTB Spring Applied Brakes

CJM's HTB spring applied brakes utilize a modular design, with optional debris cover and/or manual release, to provides an "off the shelf" solution to your braking needs. These brake components operate with minimal power consumption to disengage the brake, which reduces engagement/disengagement times and lowers drag torque.

While custom solutions are available, our HTB products provide extremely fast engagement/disengagement times when used in conjunction with a standard Carlyle Johnson Model CEC power supply. Other spring applied brakes and high torque solutions can be produced – our engineering staff is just a phone call away and ready to solve your toughest power transmission challenge.

View Specifications / Dimensions

View Specifications / Dimensions

Overview - Model HTB Electric Spring Applied Brakes

Advantages

- Highest torque in the smallest space

- Cost effective solution for exceptionally high torque in extremely small packages

Operation

- Torque from 5 lb. ft. to 6000 lb. ft.

- Floating discs for minimal torque transmission in the disengaged model

- Spring set/electrically released for stopping, positioning and holding

- Available for wet or dry applications

Customization

- Available in multiple voltages

- Available with or without manual release

- Optional brake friction pad wear indicator switch available

- Optional on/off brake status indicator switch available

- Optional integral heater for extreme environmental conditions available

- Optional sealed cover available

- Custom designs and alterations available

Typical Applications

- Imaging head positioning and holding in medical diagnostic equipment

- Stopping and holding in mechanized handling equipment

- Servo drive brakes

- Holding brakes and emergency stopping brakes for:

- Aerospace actuators

- Cranes

- Elevators/escalators

- Military actuators

- Packaging machinery

- Radar antennas

Additional Information

OTHER CJM ELECTRIC BRAKES

- Electric Jaw Brake (JEB)

- Fail-Safe Spring Set Brake (FEA)

- Medium Torque Spring Applied Brake (HBB)

- Multiple Disc Electric Brake (EMA)

- Spring Set Electric Motor Brake (EFS)

- Zero Backlash Holding Brake (JEM)